Kaolin Addition during Combustion of Olive Residue

- English

- Türkçe

Gradual introduction of increasingly restrictive legislations on emissions from combustion sources has been increasing the interest in biomass combustion. Biomass is a renewable energy source which is considered as CO2-neutral fuel and contributes to the reduction in pollutant emissions. Olive residue is the remaining part of olive after milling and extraction of the olive oil. Turkey is one of the main olive producers with 826 000 ha of olive groves and 1 768 000 tons of annual production. Alkali species, especially high concentrations of potassium, and low chlorine and sulfur content of olive residue results in operational problems like slagging and fouling during its combustion. Fluidized bed combustors are preferred in biomass combustion due to their low operation temperature (around 850˚C), which reduces occurrence of ash melting problems. However, studies on fluidized bed combustion of olive residues in beds of sand reveals that single firing of olive residue is still problematic due to the operational problems caused by high potassium content of the ash. Using additive is an option to prevent operational problems. Kaolin, which is an alumina based additive, has been shown to increase ash melting temperature of biomass and was verified to be the most effective type of additive. However, before adding kaolin to FBC combustors, effect of kaolin on combustion characteristic of olive residue needs to be determined by using non-isothermal thermo-gravimetric analysis (TGA) technique, which is an inexpensive and simple method that has been used widely in studying the combustion characteristics of fuels.

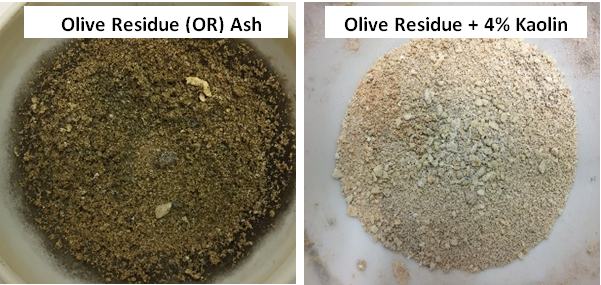

Therefore, in this study effect of kaolin addition on combustion characteristics of olive residue is investigated by using thermogravimetric analyzer combined with Fourier-transform infrared (FTIR) spectrometer in parallel with ash characteristics by using X-Ray Fluorescence (XRF) and X-Ray Diffraction (XRD). The experiments were carried out by burning olive residue with 2%, 4% and 8% by wt. kaolin at 900 ˚C. Results reveal that addition of kaolin leads to decrease in rate of weight loss during char combustion and hence increase in CO emission due to decrease in burning quality caused by dilution effect of kaolin in the mixture. Increase in HCl and SO2 concentrations with kaolin addition observed in FTIR results evaluated together with XRF and XRD results demonstrated the pathway of reactions for the capture of potassium by kaolin and formation of high melting temperature kalsilite crystals. Potassium retention in ash was found to increase up to 4% kaolin addition; however, no significant improvement in potassium retention was observed with further addition of kaolin due to abundant amount of Al and Si introduced via kaolin. The results show that optimum 4% kaolin addition decreases the alkali index below unity indicating lower tendency of fouling in combustion systems.

O. Batir, N. Selcuk, G. Kulah, “Effect of Kaolin Addition on Alkali Capture Capability During Combustion of Olive Residue”, Combustion Science and Technology (2018). (https://doi.org/10.1080/00102202.2018.1452376).