Effect of Biomass Source on Radiative Heat Transfer in FBCs

- English

- Türkçe

Gradual introduction of increasingly restrictive legislations on emissions from combustion sources has been increasing the interest in biomass combustion. However, biomass combustion brings with it some operational problems when burned alone. The most common problems encountered in industry and utility boilers are severe fouling, slagging and corrosion. Co-firing biomass with coal is a promising alternative which leads to reduce ash related problems in biomass combustion and at the same time provides an economical and environmentally friendly use of coals by reducing pollutant emissions. Nevertheless, there remain technical issues associated with biomass supply, handling and storage in co-firing applications due to its low energy density, seasonal characteristics and scattered geographical distribution

Biomass itself is usually cheap but the cost of transportation directly affects the economic feasibility of biomass co-combustion due to its low bulk density together with the high moisture content, which necessitates huge amounts of biomass to be transported for even a small share of total heat input. Optimum biomass transport distances and means of transportation are shown to depend on the capacity of the power plant and maximum distance over which biomass can feasibly be collected, which is between 25 and 100 km for highway transportation.

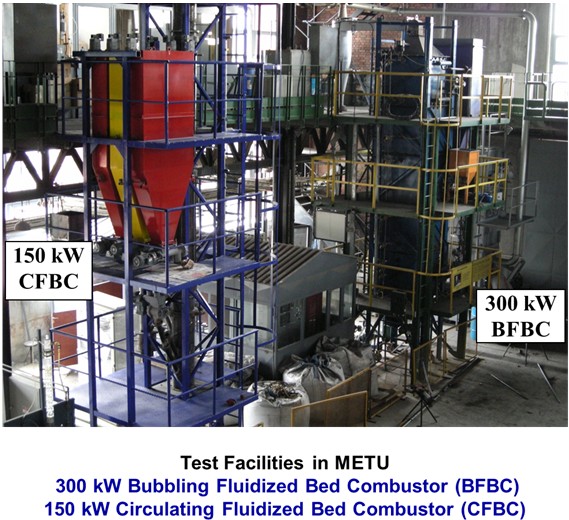

One of the possible solutions to mitigate biomass shortages encountered at high plant capacities is having access to different biomass sources within the geological boundaries designated by logistic constraints. Changing the biomass source, on the other hand, should not or at worst slightly affect the performance of the boiler. In one of their recent work, Ates et al. (2018) investigated the effect of biomass addition on radiative heat transfer for two important indigenous biomass sources, namely olive residue and hazelnut shell. Investigation is performed through mathematical modeling by using the experimental data on six combustion tests previously performed in 300 kWt Atmospheric Bubbling Fluidized Bed Combustor (ABFBC) test rig in Middle East Technical University [1].

The results show that changing the biomass source affects the radiative properties of the particles in the freeboard through the change of particle size distribution rather than optical properties, which may lead to significant variations in radiative wall heat fluxes and source terms. Based on these results, it is recommended that possible variations in particle size distribution should be elaborated if multiple biomass sources are to be utilized in the combustor.

C. Ates, N. Selçuk, G. Kulah, Effect of Changing Biomass Source on Radiative Heat Transfer During Co-Firing of High-Sulfur Content Lignite in Fluidized Bed Combustors, Applied Thermal Engineering, vol.128, pp.539–550, 2018. (https://doi.org/10.1016/j.applthermaleng.2017.09.011)

[1] Z. Gogebakan, Y. Gogebakan, and N. Selçuk, Co-Firing of olive residue with lignite in bubbling FBC, Combustion Science and Technology vol. 180(5), pp.854-868, 2008 (https://doi.org/10.1080/00102200801894117).